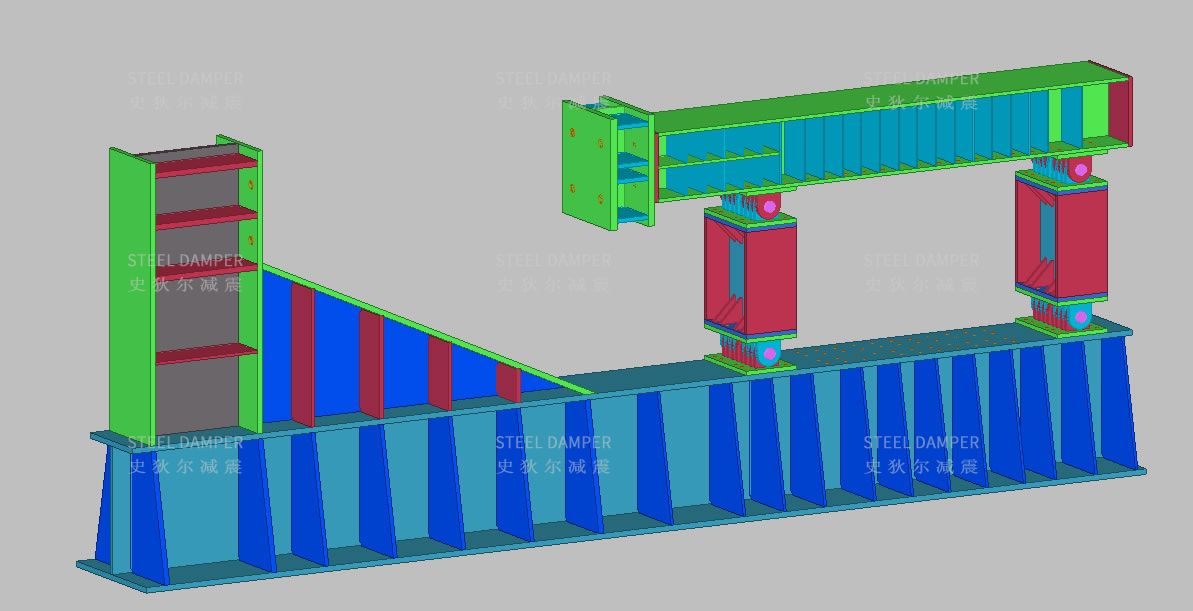

The vertical balanced loading system is our own set of static and dynamic dual-function loading systems. The loading device adopts a closed self-balancing and vertical structure design. The effective space of the entire system is 2100m, the height is 1315mm, the maximum load capacity is 1500kN, the effective test of the load system, the load-displacement stroke +125mm, can complete the test work of various specifications and sizes of dampers, especially suitable for Metallic yield damper and viscous Damping wall, Buckling restrained brace, corrugated steel wall, Sliding friction damper, Coupling-beam damper, energy dissipation damping products, etc., and it can also carry out conventional structural component loading tests.

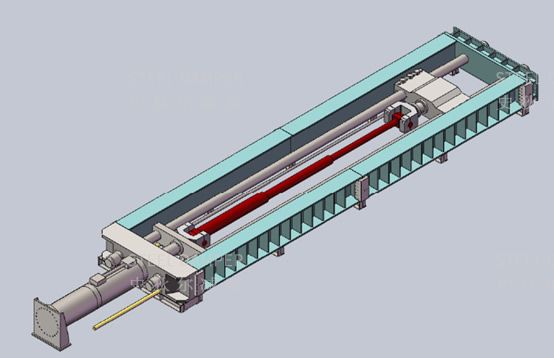

The horizontal automatic balance loading system is our own set of new static and dynamic test systems for building energy dissipation dampers. The test bench system adopts a closed overall balanced design, a horizontal structure, and an effective test space: 3000mm in length, 1500mm in width, and 800mm in height of the loading center. Center, the maximum load capacity of the system is 1200 kN, and the load-displacement stroke + 500 mm. The maximum loading speed is 1m/s, and various types of damper servo load, static load, and fatigue load tests can be carried out. It is especially suitable for performance testing of viscous dampers, friction dampers, anti-buckling supports, and viscoelastic dampers.

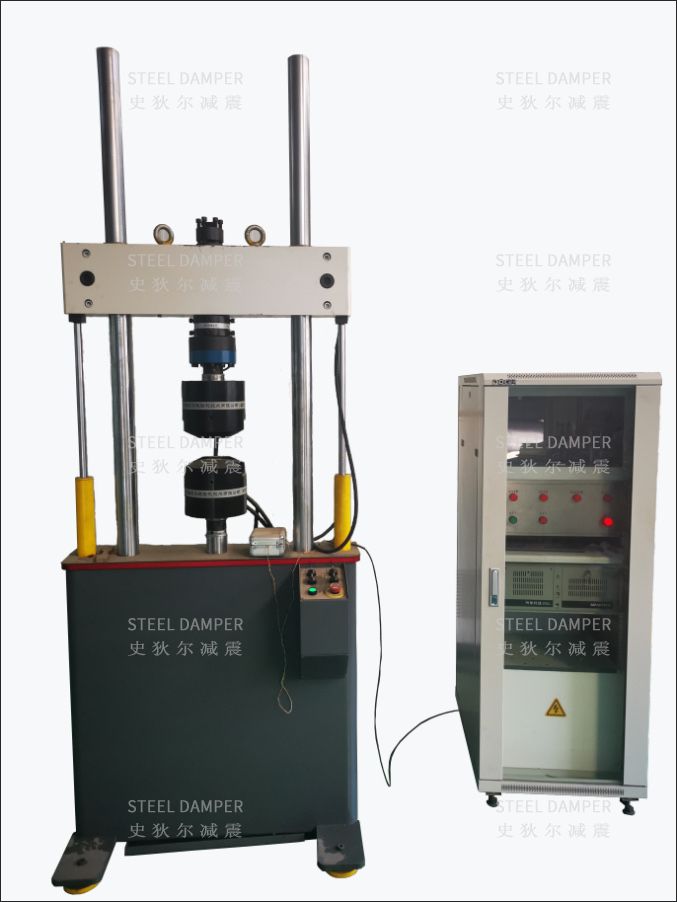

The electro-hydraulic servo dynamic and static universal test system adopts a two-column frame structure as the mainframe. The center distance of the columns is 600mm; the column diameter is 70mm; the maximum net adjustment test space: 1000 mm. With clamp, the distance between upper and lower jaws is not less than 700mm, the maximum test force of the actuator is 100kn, and the effective stroke: +75mm. It is mainly used for tensile and compression dynamic and static tests of various metals, non-metals, and composite materials, such as low-cycle metal Fatigue test, static tension, and compression test, etc.; it can also undertake fatigue and static performance tests of various structural parts and components, and can also perform creep, relaxation, and characteristic waveform fatigue tests. This system is a set of multi-functional material testing systems, which enables our company to better control the performance of various steel materials. At the same time, it also provides detailed steel-based parameters for our design damping to ensure good performance in design and production. Shock (vibration) products.