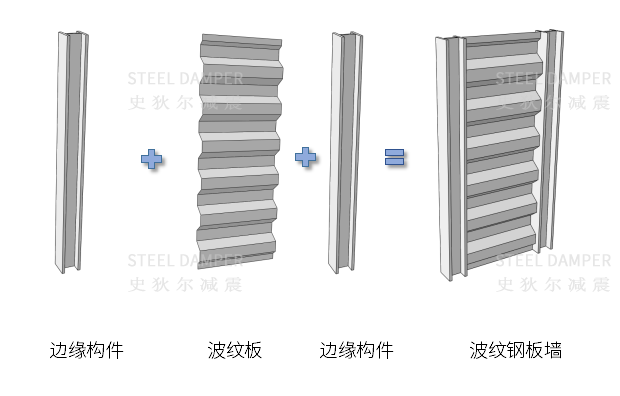

Corrugated steel plate wall is a new type of anti-lateral force system structure composed of embedded corrugated steel plates and vertical edge members. It can maintain and consume energy, provide an additional damping ratio for the structure, and reduce the response of the structure under seismic loads. The load-bearing energy consumption is a very good dual-function workpiece. Compared with the traditional or energy-dissipating damping element resisting lateral force, its main advantages are as follows:

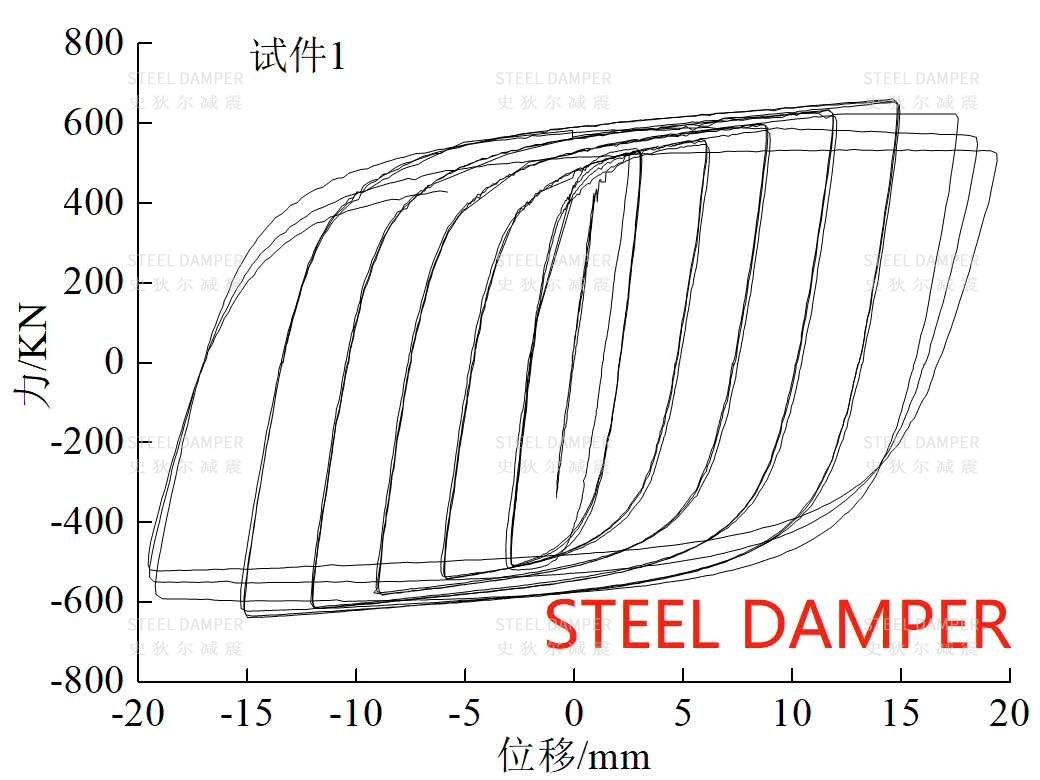

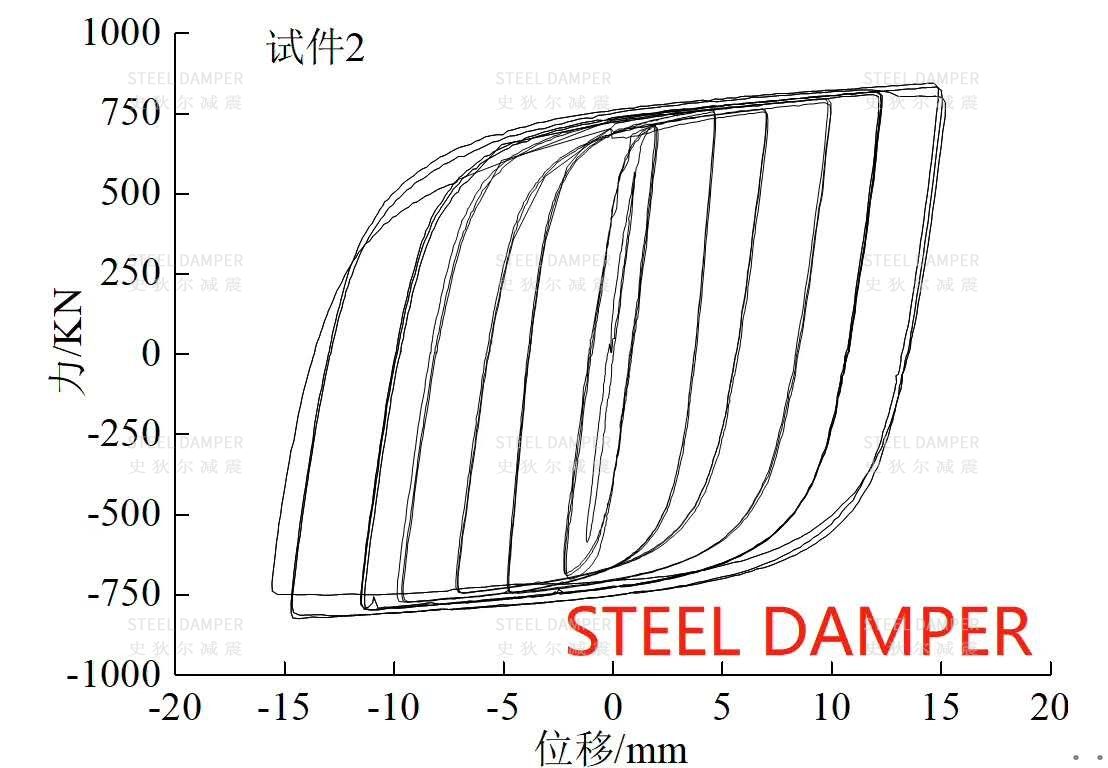

(1) By bending the steel plate itself into a "rib", the lateral bearing capacity of the component can be improved, and the hysteresis curve under cyclic load can increase its energy consumption capacity by dozens of times compared with ordinary steel plate walls.

(2)In terms of improving buckling performance, compared to the method of adding stiffened plates to flat steel plates or thickening flat steel plates, the weight of steel and the cost of welding can be saved.

(3) the structure of light weight, convenient components are installed, when seismic strengthening, building construction is extremely convenient. Can significantly shorten the construction period, has the very good economic benefits.

(4) due to dissatisfaction across to decorate, can facilitate the same frame decorate doors and Windows in the mouth of the cave, it is easier to coordinated with architectural with demand.

CSW Intro Connection Type Test

According to ripple, the direction of the corrugated steel wall can be divided into vertical and horizontal corrugated steel wall corrugated steel plate culture, two forms of steel plate wall all has the very high bearing capacity and energy dissipation performance. After a large number of calculation analysis and test research, we of the two kinds of corrugated steel wall waveform optimization, make its not appear buckling before reach ultimate bearing capacity, hysteresis curves, energy dissipation ability is good.

The connection between the corrugated steel wall and the main frame mainly includes two-side connection, three-side connection and four-side connection. Among them, the four-side connection can first come to the edge of the corrugated steel wall component, or it can be used as a sealed side plate, and the side component is directly connected to the main frame.

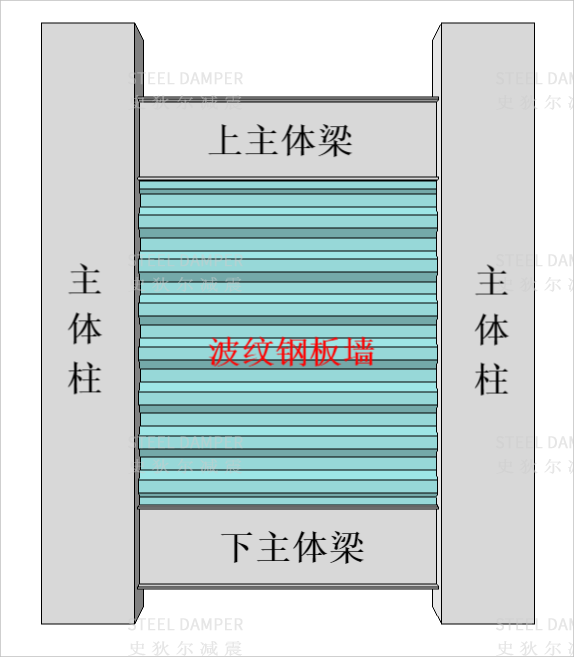

The two sides are connected by the lower end of the corrugated steel plate wall and the main beam connection of the upper and lower floors. The connection arrangement on both sides is more flexible and can be placed anywhere in the frame, which makes it easier to meet the construction needs, and the construction and installation are relatively simple. In addition, the mechanical performance analysis and comparison of the connected products of both parties facilitates parameter analysis and testing. The connection form on both sides can be used to restrain the corrugated steel wall by the edge member, and the rigidity of the outer member of the edge will be greater.

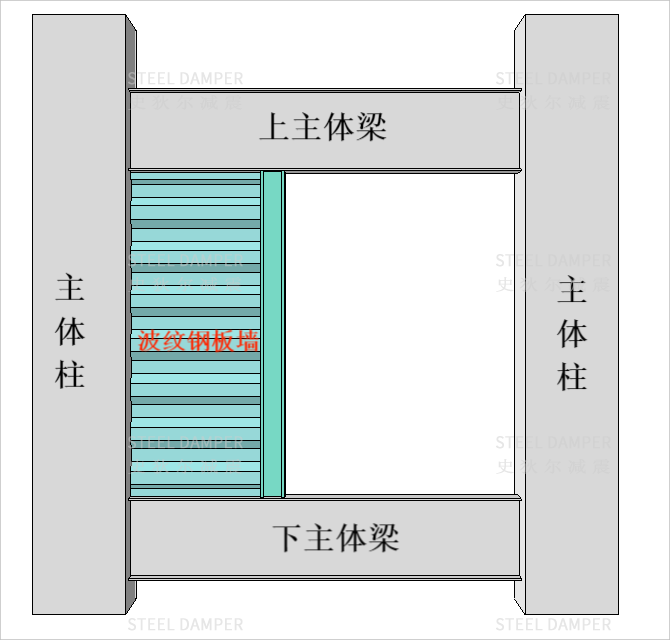

The three-sided connection is corrugated steel wall. In addition to the upper and lower ends connected with the main beam, one side is also connected with the main column.

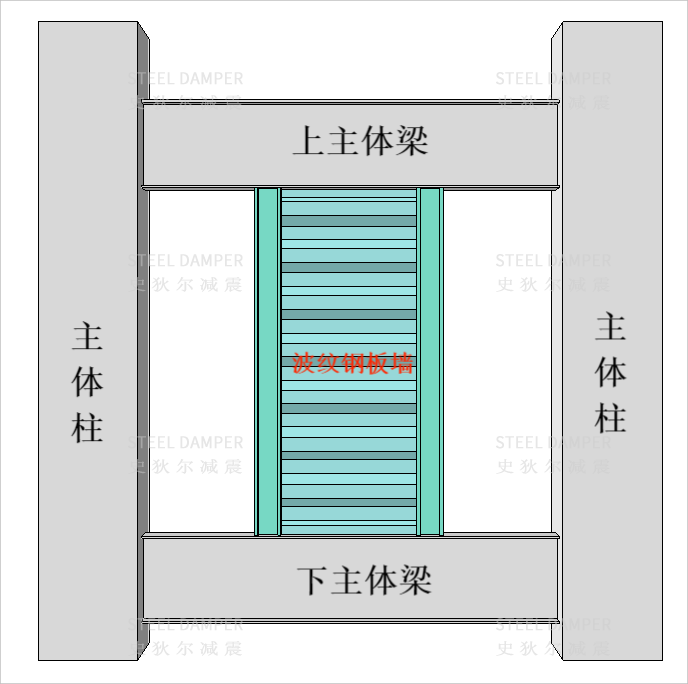

Four-side connection is within the framework of the whole piece of corrugated wall embedded in the main body, with all round the body of the beam-column connections.

Connected by trilateral or quads, can use the subject column stiffness constraints, corrugated surface of the wall outside buckling, compared to the connection on both sides, just outside the surface at the edge of the component virtual demand is relatively lower. But when connect corrugated steel square or triangles size need to be matching with body frame size, relative to the requirement of construction precision, decorate on basic is fixed.

Two-side connection

Three-side connection

Four-side connection

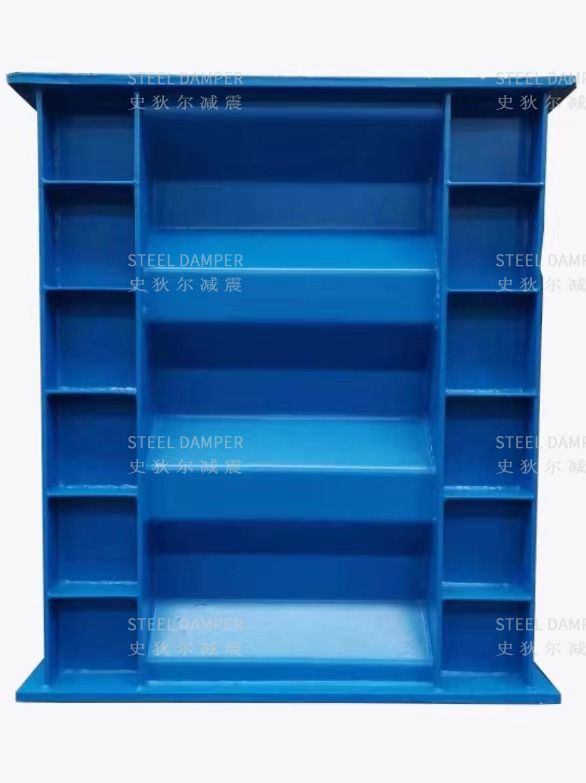

Test piece

Test device

Test device

Hysteresis curve

Hysteresis curve