DBRB IntroConnection Type

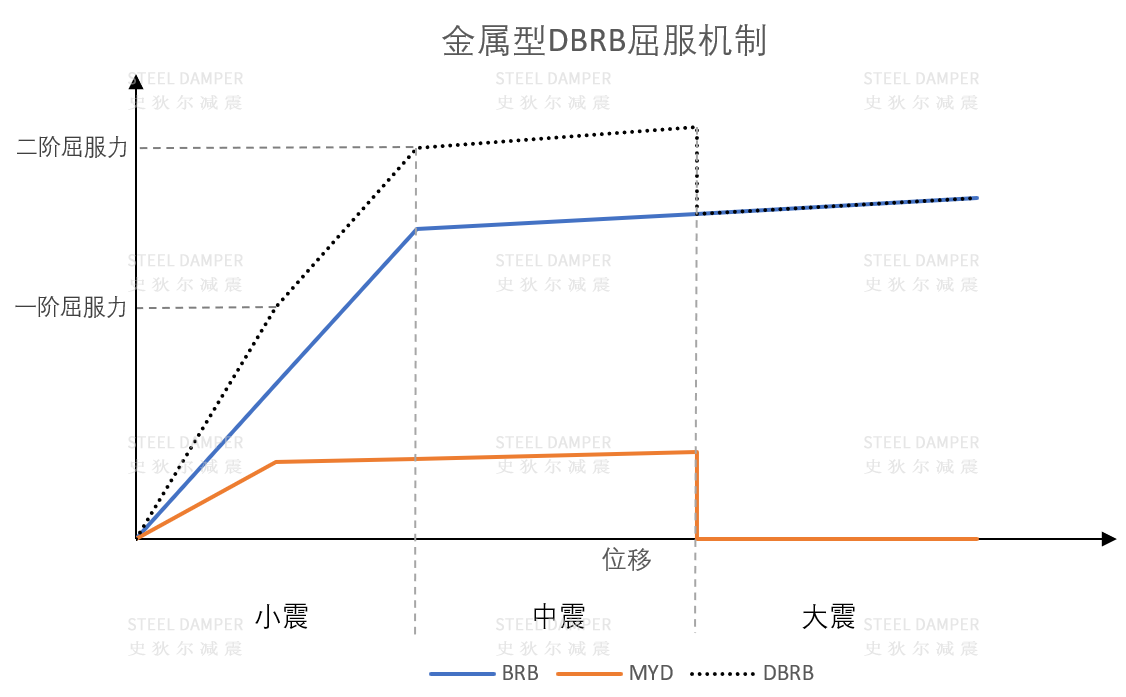

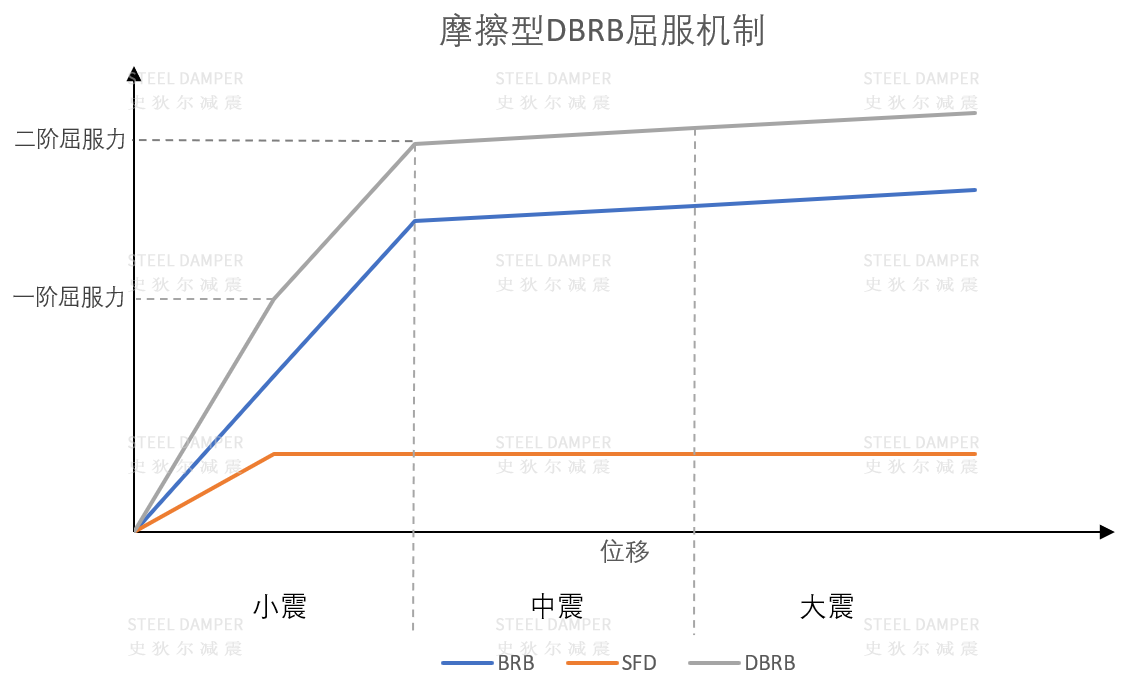

Traditional shock absorption products can only be controlled for one kind of earthquake situation. For example, friction dampers can generate and consume energy in small earthquakes, but cannot provide sufficient stiffness in large earthquakes; Ordinary BRB can enter the buckling energy dissipation stage during moderate or large earthquakes, but it is in the elastic stage during small earthquakes and cannot play an energy dissipation role. Two-level-yielding Buckling restrained brace (DBRB) has high energy consumption and good rigidity in small, medium and large earthquakes, which can better protect the safety of the structure.

For small earthquakes, the first-order damper yields to the working state of energy dissipation damping, and the second-order BRB part is in the elastic working stage; for medium earthquakes, the first-order damper continues to maintain the working state of energy dissipation and damping, and the second-order BRB yields to energy dissipation and damping. Working state: In the event of a major earthquake, the first-order damper can be designed to exit or continue to work, and the second-order BRB maintains the working state of energy dissipation damping to ensure that the main structure does not collapse.

Generally, the products of DBRB manufacturers are of metal type. This kind of product is deformed due to large deformation during an earthquake, and the metal damper will quit working because it needs to be replaced after the earthquake is damaged. The friction type DBRB independently developed by our company has the advantage that the designed friction damper components have large displacement, and can still maintain the energy dissipation and damping working state during a major earthquake, and there is still energy dissipation after the earthquake, and it can not be replaced if it is qualified.

1. The appearance size of DBRB is determined by the product length and the second-order yield capacity. The first-order yield of the bearing capacity does not affect the appearance size. The first-order yield capacity is generally 10% of the second-order yield capacity;

2. example: the second order the yield capacity of 4000 kn, product length is 4800 mm, exterior size is 350 mm x 350 mm;

3. yielding capacity or product exactly corresponding to the data in the table above, the length can be reference for similar data to determine.

2. example: the second order the yield capacity of 4000 kn, product length is 4800 mm, exterior size is 350 mm x 350 mm;

3. yielding capacity or product exactly corresponding to the data in the table above, the length can be reference for similar data to determine.

Bolted connection

The two ends of the buckling restraint support and the corresponding gusset plate are pre-opened with screw holes, and high-strength bolts are used to connect each component.

Advantages: high installation efficiency, low requirements for personnel, overall appearance, and moderate price.

Disadvantages: There are many factors affecting the installation angle, and the existence of errors makes the accuracy difficult to control, and the adaptability is the worst.

The two ends of the buckling restraint support and the corresponding gusset plate are pre-opened with screw holes, and high-strength bolts are used to connect each component.

Advantages: high installation efficiency, low requirements for personnel, overall appearance, and moderate price.

Disadvantages: There are many factors affecting the installation angle, and the existence of errors makes the accuracy difficult to control, and the adaptability is the worst.

Welded connection:

The buckling restraint support is connected with the gusset plates at both ends directly by butt welds.

Advantages: high installation flexibility, strong adaptability, economical price, high fault tolerance rate.

Disadvantages: Need to consider the residual stress caused by welding, which requires high welders' ability.

The buckling restraint support is connected with the gusset plates at both ends directly by butt welds.

Advantages: high installation flexibility, strong adaptability, economical price, high fault tolerance rate.

Disadvantages: Need to consider the residual stress caused by welding, which requires high welders' ability.

Pinned connection

The two ends of the buckling restraint support and the gusset plate need to be pre-opened with round holes, and each side is connected by a pin.

Advantages: the highest installation efficiency, lower requirements for workers, and the most beautiful overall.

Disadvantages: the most expensive price, high precision requirements, poor installation flexibility.

The two ends of the buckling restraint support and the gusset plate need to be pre-opened with round holes, and each side is connected by a pin.

Advantages: the highest installation efficiency, lower requirements for workers, and the most beautiful overall.

Disadvantages: the most expensive price, high precision requirements, poor installation flexibility.