SFD IntroConnection Type Test

The sliding friction damper consumes input energy through frictional sliding between components. Because of its simple structure, stable performance, and large damping force, it has been adopted by engineering. For structures with friction dampers, under normal loads, the friction dampers provide additional rigidity to the structure without sliding; under the action of strong earthquakes, the friction dampers absorb seismic input energy through sliding friction power consumption. The structure provides additional damping, which reduces the structural response.

The development of friction dampers began in the 1970s. After decades of development, it has formed a variety of forms:

A. Friction energy dissipation nodes, such as limit slip bolt joints, long hole bolt hole nodes, etc.;

B. Plate friction dampers, Pall friction dampers, T-core plate friction dampers, etc.;

C. Cylinder friction dampers, Sumitomo friction dampers, steel pipe friction dampers, etc.;

D. Compound friction dampers, such as friction ring-composite damper, electric pressure-friction damper, etc.

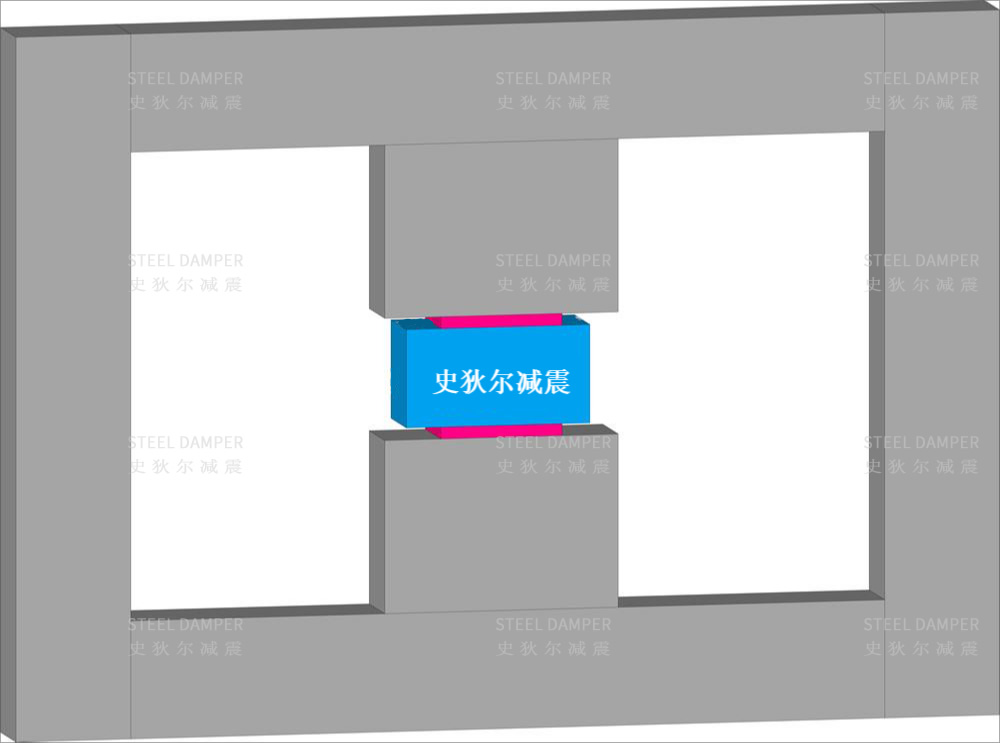

Wall type connection

The decoration position is relatively flexible and can replace the addition in the original building wall without affecting the use of the building space. The dampers can also be arranged on both sides according to the needs of the building function. The use of concrete reduces the cost of the damper in the installation process and has a good cost performance. However, the use of cantilever culture increases the force of the beam structure, so attention must be paid to the design. Wall type connection is mainly composed of reinforced concrete cantilever wall, cantilever wall embedded parts , and damper component connection group.

The construction process is as follows:

Construction preparation-cantilever steel bar lashing installation-the embedded part is hoisted to the installation position and rechecked-embedded part installation, fixed-support cantilever wall formwork-pouring concrete-friction damper installation

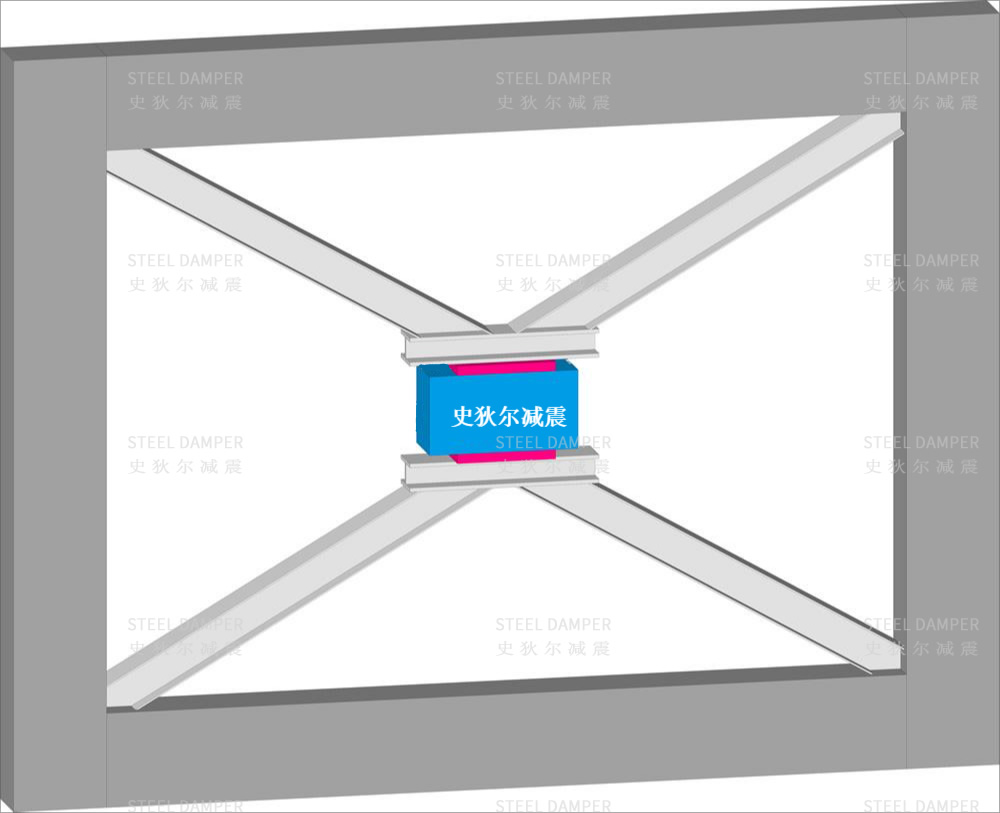

Supported type connection

It is suitable for new construction and reinforcement and renovation projects, especially for reinforcement and renovation projects. Its embedded parts are located at the joints of structural beams and columns. The force transmission effect is good and does not increase the burden of structural beams. To a certain extent, it will occupy building space. The location of the support is often unable to leave enough space for decoration such as doors and windows. The amount of steel used for steel supports and joists has also increased to a certain extent, and the cost of construction is relatively high. The friction damper support type connection method is mainly composed of frame beam-column embedded parts, node connecting plates, steel joists, inclined supports, dampers and other components.

The construction process is as follows:

beam and column embedded parts setting out, processing and production-beam and column embedded parts installation-beam slab column concrete pouring-support installation, fixing-steel beam welding-friction resistance installation.

Beam type connection

Commonly used in shear wall structures, especially suitable for residential projects, instead of concrete beams. Taking into account the requirements of damping, this kind of structure is often dissipated through the Coupling-beam damper in the structural system of input seismic energy. The biggest advantage of beam connection is that it will hardly cause any adverse effects on the use of building space, and it has a good energy dissipation effect, which "virtually reduces the cost of ordinary seismic structural schemes within a certain range."

The construction process is as follows:

material entry acceptance-embedded parts installation-steel formwork construction-concrete pouring-coupling beam friction damper installation.

| SFD mechanical performance requirements-conventional performance | ||

| Serial number | Item | Performance requirement |

| 1 | Sliding damping force | The deviation of the actual measured value of the sliding damping force of each product should be ±15% of the design value; the average of the actual measured value deviation should be ±10% of the design value |

| 2 | Starting slip displacement | The deviation of the actual measured value of the sliding displacement of each product should be ±15% of the design value; the average of the deviation of the actual measured value should be ±10% of the design value |

| 3 | Initial stiffness | The deviation of the actual measurement value of the initial stiffness of each product should be ±15% of the design value; the average value of the deviation of the actual measurement value should be ±10% of the design value |

| 4 | Ultimate load | The deviation of the measured value of the ultimate load of each product should be ±15% of the design value; the average of the deviation of the measured value should be ±10% of the design value |

| 5 | Limit displacement | The limit displacement value of each measured product should not be less than the limit displacement design value |

| 6 | Hysteresis curve area | The deviation of the measured value of the envelope area of the hysteresis curve in any cycle should be ±15% of the design value; the average of the deviation of the measured value should be ±10% of the design value |

| SFD mechanical performance requirements-fatigue performance | ||

| Serial number | Item | Performance requirement |

| 1 | Friction load | The measured product is continuously loaded for 30 cycles under the design displacement, the maximum and minimum damping force of any cycle should be ±15% of the average value of the maximum and minimum damping force of all cycles |

| 2 | Hysteresis curve | (1) The measured product is continuously loaded for 30 cycles under the design displacement. The maximum and minimum damping force at zero displacement in any cycle shall be ±15% of the average value of the maximum and minimum damping force at zero displacement in all cycles (2) Under the design displacement of the measured product, the maximum and minimum displacements of the damping force at zero in any cycle shall be ±15% of the average value of the maximum and minimum displacements of the damping force at zero in all cycles |

| 3 | Hysteresis curve area | The measured product is continuously loaded for 30 cycles under the design displacement, and the hysteresis curve area of any cycle should be ±15% of the average value of the hysteresis curve area of all cycles |