VFD IntroConnection Type Test

Viscous damper damping energy consumption principle: when the external vibration (earthquake or wind) is passed to the structure, the structure of the damper movement. The formation pressure difference on both ends of the piston, medium (silicone) through from the damping structure, resulting in a damping force and realize the change of energy (mechanical energy is converted into heat energy produced by vibration, so as to reduce the vibration of the structure.

Composition and characteristics

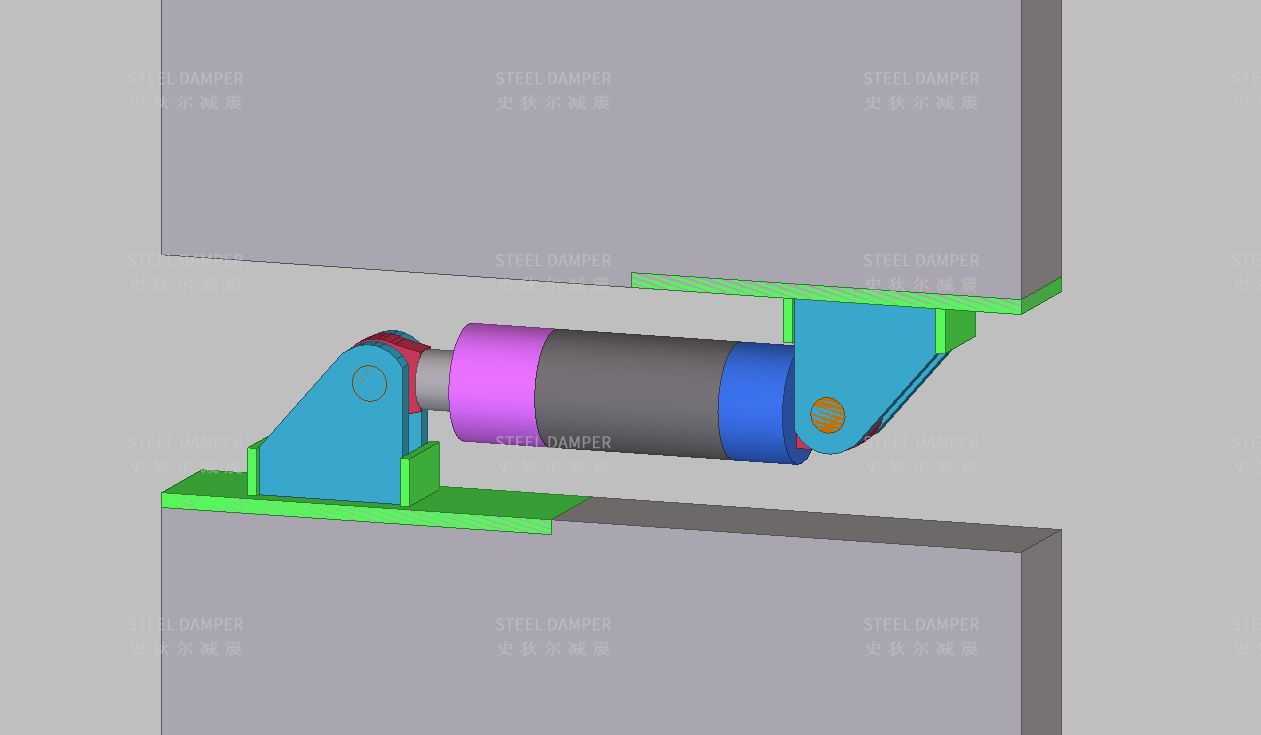

1. the oil cylinder, piston, piston, liner, medium, the pin head of this a few parts;

2. Medium using low viscosity, medium;

3. Low speed friction damping is low, less than 10% rated load;

4. products long life, stable performance, xiao gu seismic and wind resistance, can be used reciprocating;

5. Hydraulic medium stability, flame resistant, ageing resistance, good sealing, sealers adopt good compatibility with the media material.

1. the oil cylinder, piston, piston, liner, medium, the pin head of this a few parts;

2. Medium using low viscosity, medium;

3. Low speed friction damping is low, less than 10% rated load;

4. products long life, stable performance, xiao gu seismic and wind resistance, can be used reciprocating;

5. Hydraulic medium stability, flame resistant, ageing resistance, good sealing, sealers adopt good compatibility with the media material.

Resistance with processing workshops

machining center

Model representation method:

VFD-NLx2000 250VFDS

VFD: viscous fluid damper

NL style: L for linear,NL for nonlinear

2000: maximum output damping force (load rating) kN

250: design xu displacement (stroke) mm

VFD-NLx2000 250VFDS

VFD: viscous fluid damper

NL style: L for linear,NL for nonlinear

2000: maximum output damping force (load rating) kN

250: design xu displacement (stroke) mm

| 序号 | 最大(设计)阻尼力(kN) | 销轴直径(mm) | 阻尼器外径(mm) | 行程(设计位移)(mm) | 销销距(行程50mm时)(mm) |

| 1 | 50 | 40 | 123 | 10-100 | 830 |

| 2 | 100 | 40 | 123 | 10-100 | 830 |

| 3 | 150 | 50 | 123 | 10-100 | 830 |

| 4 | 200 | 50 | 123 | 10-100 | 830 |

| 5 | 250 | 50 | 162 | 10-200 | 900 |

| 6 | 300 | 50 | 162 | 10-200 | 900 |

| 7 | 350 | 60 | 176 | 10-300 | 915 |

| 8 | 400 | 60 | 176 | 10-300 | 915 |

| 9 | 450 | 60 | 176 | 10-300 | 915 |

| 10 | 500 | 60 | 197 | 10-500 | 935 |

| 11 | 550 | 60 | 197 | 10-500 | 935 |

| 12 | 600 | 60 | 197 | 10-500 | 935 |

| 13 | 650 | 80 | 215 | 10-500 | 970 |

| 14 | 700 | 80 | 215 | 10-500 | 970 |

| 15 | 750 | 80 | 215 | 10-500 | 970 |

| 16 | 800 | 80 | 215 | 10-500 | 970 |

| 17 | 850 | 100 | 239 | 10-500 | 1050 |

| 18 | 900 | 100 | 239 | 10-500 | 1050 |

| 19 | 950 | 100 | 239 | 10-500 | 1050 |

| 20 | 1000 | 100 | 239 | 10-500 | 1050 |

| 21 | 1200 | 120 | 296 | 10-800 | 1120 |

| 22 | 1500 | 120 | 320 | 10-800 | 1190 |

| 23 | 2000 | 140 | 374 | 10-800 | 1220 |

| 24 | 2500 | 160 | 420 | 10-800 | 1300 |

| 25 | 3000 | 200 | 464 | 10-800 | 1340 |

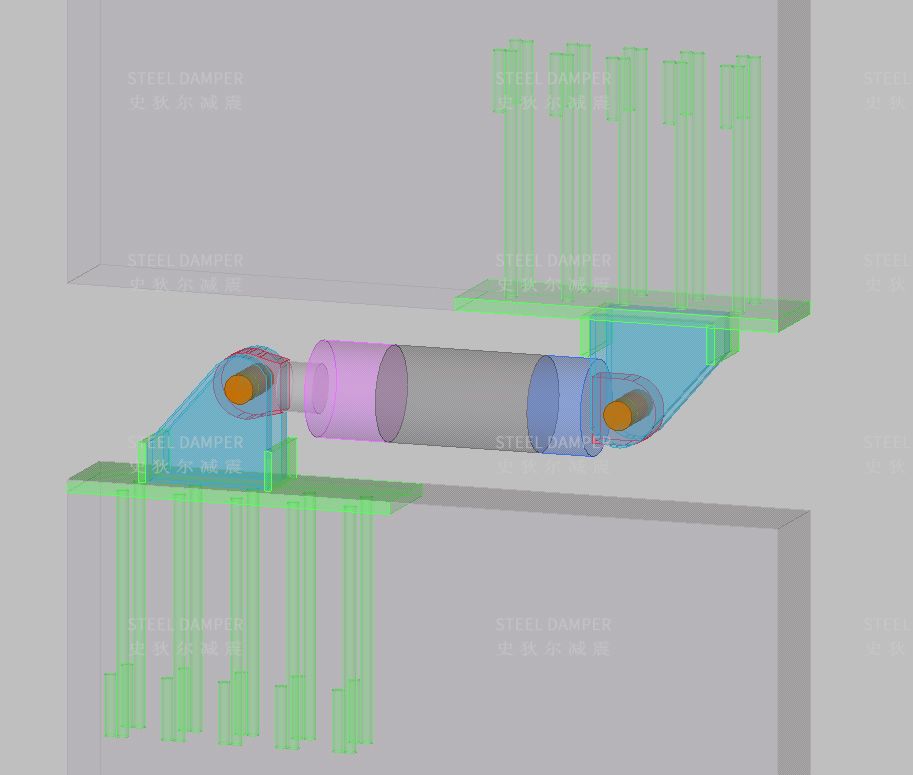

1 The steel bars of the upper and lower cantilever beam walls must be arranged in strict accordance with the design drawings, and attention should be paid to the control of the position, elevation and verticality of the steel bars.

2 When the embedded parts are installed on the cantilever wall, the position arrangement should be strictly in accordance with the requirements of the drawings, so as to prevent the embedded parts from shifting in the concrete. After the arrangement is completed, the embedded parts must be fixed by spot welding and cantilever steel between the steel bars, welding and pouring concrete Attention should be paid to ensure that it is parallel to the board surface of the embedded parts. When the concrete is paid attention to, there should be no quality problems such as drums, honeycombs, pits, leaking ribs, and cracks.

3 When installing the damper, you must first assemble the lug plate and the damper with a pin before welding the lug plate and the embedded parts. Pay attention to the welding groove of the lug plate facing outwards, and the lug plate welding to ensure that there are no cracks and no leakage on the external smooth part. Welding and virtual welding problems.

JG/T 209-2012 Building Energy Dissipation Damper

The number of tests of the same type and specifications of the same project, standard fortifications account for 20%, key fortifications account for 50%, and ad hoc fortifications account for 100%, but no less than 2, and the number of tests is 100%.

Test items: limit displacement, maximum damping force and damping coefficient, damping index. Hysteresis curve

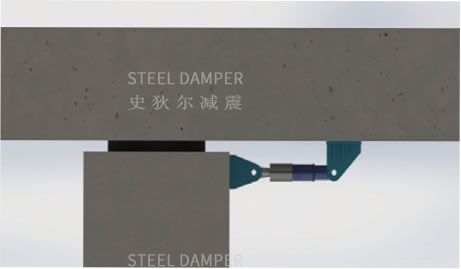

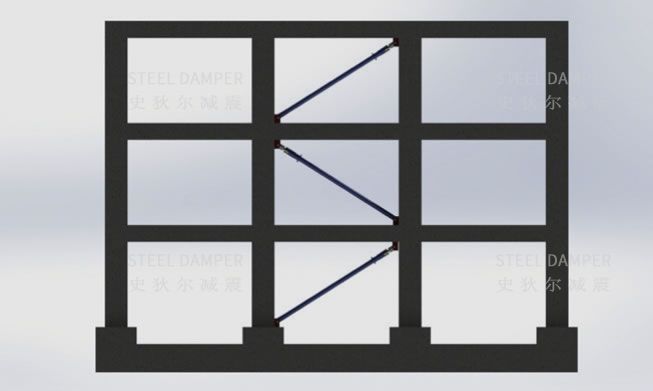

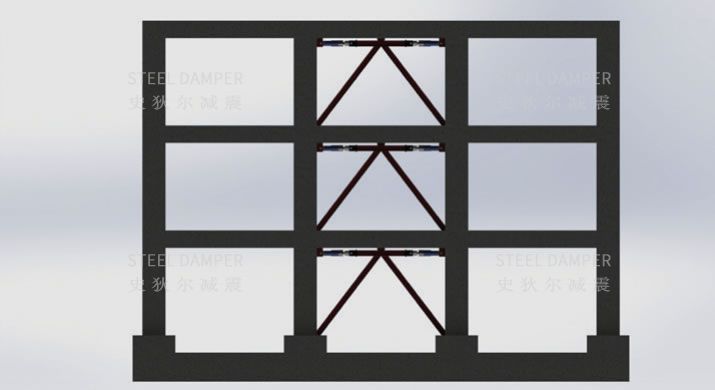

Damper is inclined support (building connection)

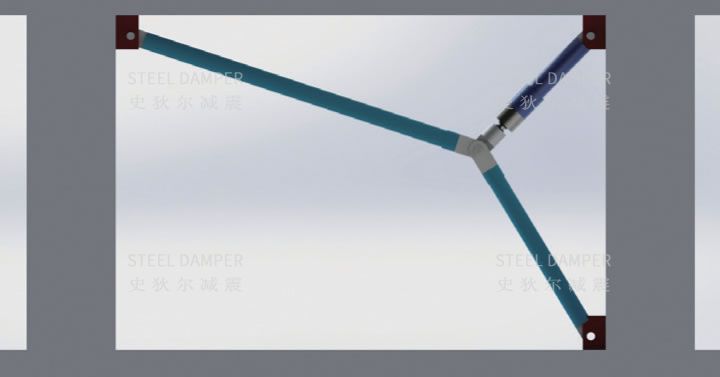

Damper herringbone support (building connection)

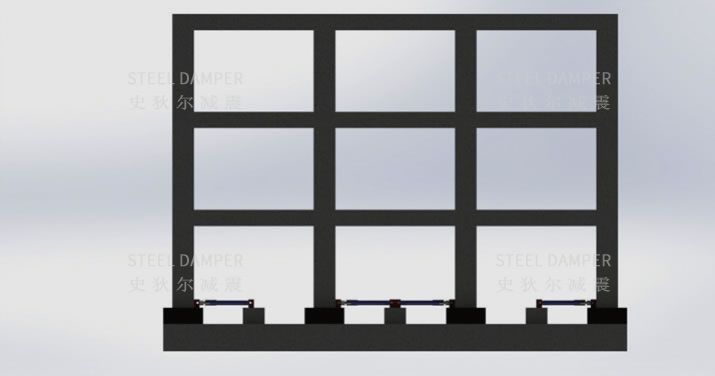

Damper lateral support (building connection)

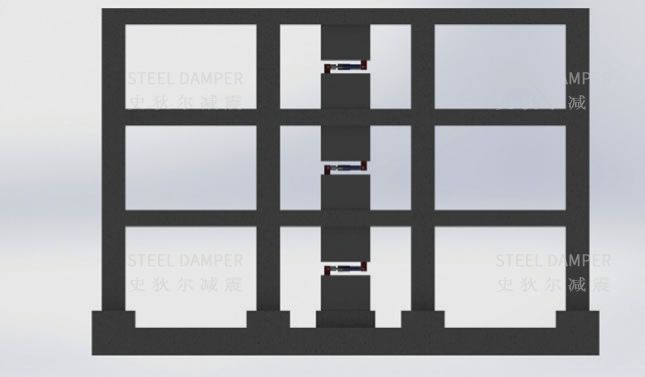

Damper Shear Wall (building connection)

Damper lock type(building connection)

Dampers for stay cables (bridge connection)

Dampers for piers and bridges(bridge connection)